New Home

Welcome to Thriveni

DRC

India

Indonesia

Australia

We work for positive impact

9.5B+ USD per year

Output

Value

01

02

70+

Projects Delivered

250M+ tonnes per year

Product Capacity

03

04

85% CO2 reduction

by

HEMMs Rebuilt

The Thriveni

Rebuild Centre

The Thriveni Rebuild Centre is a unique, innovative and unparalleled engineering and manufacturing facility that can rebuild HEMMs across global OEMs.

It has successfully refurbished more than 1000 HEMMs, including 300 tonne trucks and 40 cubic metre shovels.

The Thriveni Edge

What we do

01

Exploration

02

Project Execution

03

Engineering Procurement Construction

04

Development and Operations

05

Mineral Processing

06

Equipment Refurbishment

07

Logistics

08

Marketing

What We Do

01

Exploration

02

Project Execution

03

Engineering Procurement Construction

04

Development and Operations

01

Exploration

02

Project Execution

03

Engineering Procurement Construction

04

Development and Operations

05

Mineral Processing

06

Equipment Refurbishment

07

Logistics

08

Marketing

05

Mineral Processing

06

Equipment Refurbishment

07

Logistics

08

Marketing

Case

studies

Sorry, we couldn't find any posts. Please try a different search.

Sorry, we couldn't find any posts. Please try a different search.

Case

Studies

Sorry, we couldn't find any posts. Please try a different search.

Sorry, we couldn't find any posts. Please try a different search.

Sorry, we couldn't find any posts. Please try a different search.

Our Ventures

Thrive with Thriveni.

Partnerships form the bedrock of our growth strategy.

Sustainability

Community>>

The things we do are built around the aspirations of local communities.

Environment>>

All our efforts are built around the philosophy of minimal impact to the environment.

Cutting Carbon>>

At Thriveni, we undertake several initiatives to minimise our carbon footprint.

Social Media

Follow us to know more

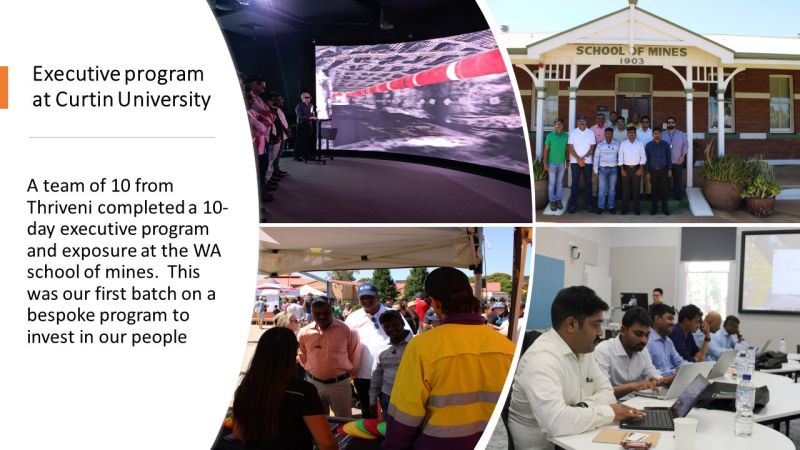

Glimpses from our first batch of executive training at the WA School of Mines, Australia

Lloyds Metals and Energy Ltd Iron Ore Mine at Surjagarh receives a 5-star Rating from Indian Bureau of Mines

Congratulating our team of ten who completed an executive program at Curtis University

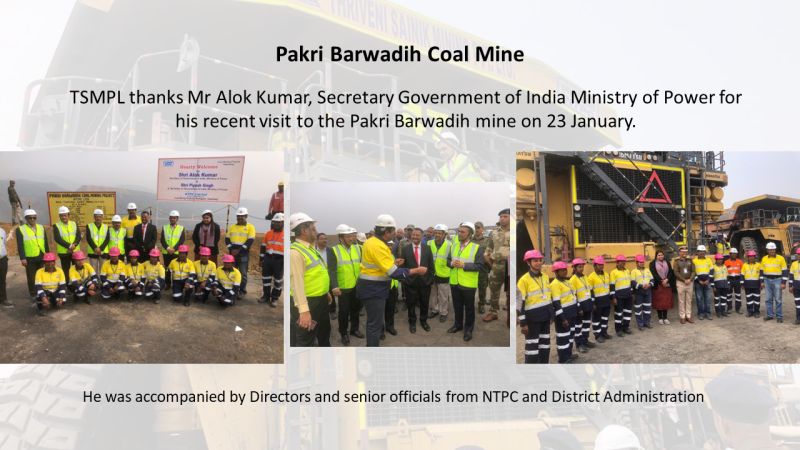

The Pakri Barwadih mine receives a distinguished visitor